Rethinking How & Where We Make: Local, Fast, and “Custom-Enough”

Janne Kyttanen has never been interested in “business as usual.” From Shrek-shaped popsicles at Universal Studios to a two-part shoe that bypasses the complexity of legacy manufacturing, the Founder & CPO of What The Future is rewriting the playbook on how things are made. His latest move: a pilot plant in Amsterdam designed to prove that local, high-velocity factories can compete with Asia on cost and impact.

In this conversation, Janne shares candid views on sustainability gimmicks, the limits of 3D printing, why AI only matters when it connects digital to tangible, and why simplicity beats décor in footwear design.

Watch the full conversation below!

Don’t have time to watch the full video? Scroll down for a summary of key takeaways and noteworthy quotes.

Key Takeaways

1. Curiosity over aesthetics sparked a 30-year journey

Kyttanen never set out to design “pretty things.” As a student, he was more interested in how products were made, and how to rewire the supply chain for efficiency and sustainability. That curiosity led him to experiment with 3D printing and set the foundation for a career in rethinking how we make.

I was more curious about how things were made globally…how do we make if we were to rewire the entire planet in an efficient and sustainable way?

2. Food and footwear share the same backbone

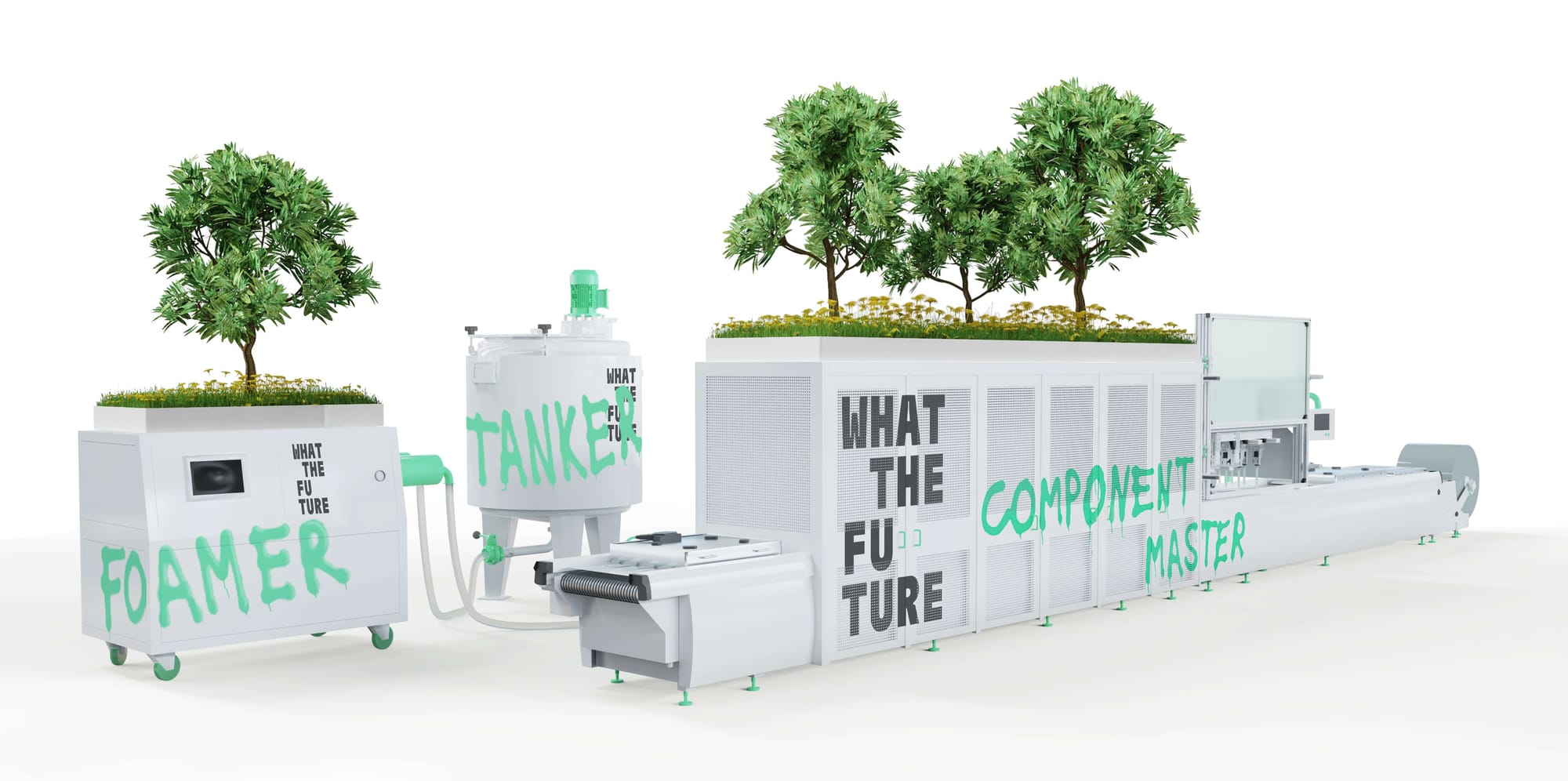

At first glance, ice cream and shoes couldn’t be further apart. But for Kyttanen, both are proof points for a universal manufacturing method that processes liquids, gels, or pastes into finished products, and at any scale, from one to a million. That’s why What The Future can sell a Shrek popsicle in Orlando and build a two-part shoe in Amsterdam, all with the same underlying technology.

We’re not actually in the ice cream or footwear business…we’re making a high-velocity local manufacturing production technique that can be deployed anywhere in the world, in any kind of liquid, paste, or gel ingredient.

3. Factories speak louder than PowerPoints

Brands don’t buy slide decks; they buy proof. By building his own facilities – from ice cream factories to a pilot footwear plant in Amsterdam – Kyttanen reduces risk for partners and shows what “local at scale” can look like in practice.

If you show somebody a PowerPoint showing the machine and the economics, they won’t believe you. They only believe once you make it yourself.

4. Simplicity is the true innovation

Legacy footwear manufacturing relies on dozens of parts and countless hands. What The Future’s approach strips it back to two pieces, directly injected into a finished shoe. For Kyttanen, innovation isn’t about décor or layers; it’s about removing friction until the product makes itself.

Our shoes are incredibly simple, and there’s only two parts…They come from the end of the line as a ready shoe.

5. Sustainability must meet the P&L test

Kyttanen is blunt: sustainability has become a gimmick when it doesn’t align with business fundamentals. True change comes when ecological responsibility and commercial viability overlap.

You have to be able to make sustainable products for the environment and sustainable for the business. Then we have an opportunity to create impact.

6. Copy-pasting Asia doesn’t work in Europe

Too many brands assume localising production means replicating Asia’s labour-intensive model with robots. Kyttanen calls this a dead end: without rethinking design, supply chains, and materials, automation alone won’t deliver.

The myth is trying to replicate the Asian way of making things in Europe. I haven’t seen that working.

7. AI only matters when it connects digital to tangible

Hype and one-off digital experiments don’t impress Kyttanen. What does? Using AI to turn consumer demand signals into products that can be manufactured – one or a million at a time – with no bottleneck between digital buzz and physical supply.

We’re creating digital–tangible workflows…if we get a million hits online, we can actually make a million.

8. Innovation should live beyond the design studio

Too often, footwear innovation is confined to aesthetics. Kyttanen argues that creativity belongs in supply chains, materials, and processes – and that siloed corporate structures are holding it back.

Creativity isn’t just in the look of a shoe – it’s in supply chains, processes, and materials.

9. Scale is the hidden challenge of decentralization

Making one shoe or ten is easy. Making ten thousand identical pairs with quality, speed, and consistency is an entirely different ballgame. Kyttanen points out that the cultural shift is just as hard as the technical one.

It’s easy to make one, ten, or a hundred. But once you go into the thousands, it’s a different story…going from one-off local to making millions is an entirely different ballgame.

Bold, simple, and custom-enough: the 2-part shoe points to a new footwear future.

10. Redefining value: ‘custom-enough’ sits between one-off and mass

Kyttanen doesn’t believe the future is purely bespoke or purely mass-produced. Instead, he sees a middle ground where products are repeatable but still differentiated enough to create value and loyalty.

We believe in the custom-enough. We can make mass products, but we don’t want to replicate what’s already in the market – we want to create that middle ground.

From Universal Studios kiosks to an experimental Amsterdam shoe plant, Janne Kyttanen is proving that the future of manufacturing is local, fast, and built on simplicity. He’s challenging brands to rethink not just what they make, but how they make it, and to consider whether “custom-enough” might be the new sweet spot between one-off hype and mass production.